Aqueous Degreasing Solutions

OXY:

The OXY series represent a range of sprying washing machines for small and medium productions, for the treatment of metal surfaces, with a washing solution of water and detergent.

Enterely built in Stainless Steel, with dimensions related to the size of the parts to be treated, can be equipped with all devices such as air blowing, hot air drying, oil separator, microfiltration.

Standard configuration:

- Construction in Stainless Steel;

- Load capacity from 100kg to 350kg;

- Stainless Steel basket with diameter of 600, 800, 900 and 1150mm;

- Basket rotation on vertical axis by gearmotor with clutch;

- Machine with one or two tanks;

- Tanks with inspection hatch and manual valve for total emptying;

- Washing solution heated electrically;

- Pumps, ramps and noozles in Stainless Steeel;

- Manual opening lid with gas pistons;

- 500µm static filter between washing chamber and tanks;

- Emergency stop;

- CE/UL standards.

ATR:

the ATR series represent a range of hydrokinetik washing machines by spray and immersion, for the treatment of metal surfaces, with a washing solution of water and detergent.

Entirely built in Stainless Steel, involves the use of a basket to hold the parts to be washed, and can be equipped by all devices such air blowing, hot air drying, vacuum drying, Ultrasonics, oil separator, microfiltration, automatic loading/unloading systems.

Standard configuration:

- Construction in Stainless Steel;

- Full paneling with safety tray;

- Load capacity from 100kg to 600kg;

- Basket dimensions: 450x300xH200mm, 600x300xH200mm, 900x500xH400mm et 1200x800xH600mm;

- Basket rotation on horizontal axis by gearmotor with clutch;

- Machine with one or two tanks;

- Tanks with inspection hatch and manual valve for total emptying;

- Washing solution heated electgrically;

- Pumps, ramps and noozles in Stainless Steel;

- Automatic vertical sliding door operated by a pneumatic cylinder and microswitch;

- Static filter in Stainless Steel between washing chamber and tanks;

- Computer PLC Siemens;

- Emergency stop;

- Vapors extractor;

- CE/UL standards

PASSO-PASSO:

the Passo-Passo series is circular tunnel or “carousel” washing system for the treatment of metal surfaces, with a washing solution of water and detergent.

Designed for high productivity, it is also ideal for installation in robotic islands.

Entirely built in Stainless Steel with full paneling and safety tray, it is made up of different sectors as required (washing, rinsing, blowing, drying, etc.), and can be equipped by all devices such air blowing, hot air drying, oil separator, microfiltration.

Standard configuration:

- Construction in Stainless Steel;

- Load capacity 20kg;

- Useful dimensions for each sector: diameter from 200 to 320mm, heigh 450mm;

- Carousel rotation on vertical axis by gearmotor and clutch;

- Machine with one or more tanks;

- Tanks with inspection hatch and manual valve for total emptying;

- Washing solution heated electically, by gaz naturel, LPG, diesel or steam;

- Pumps, ramps and noozles in Stainless Steel;

- Computer PLC Siemens;

- 500µm static filter in Stainless Steel between washing sectors and tanks;

- Emergency stop;

- Single front station for loading/unloading protected by safety barriers;

- Manual or robotic loading/unloading;

- Vapors extractor;

- CE/UL standards.

Configuration and number of sectors can be customized

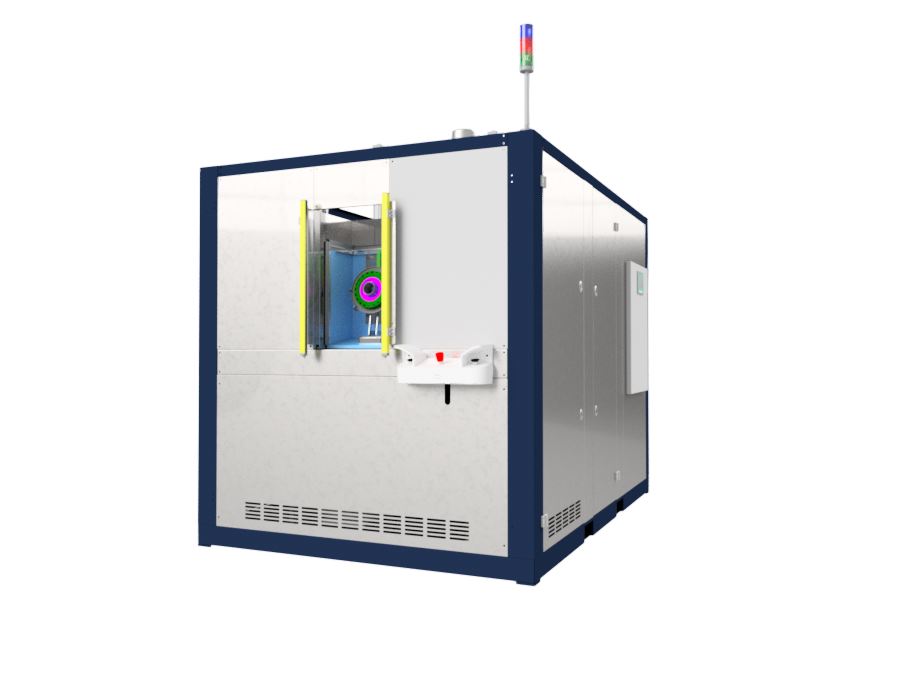

BASIC:

the BASIC series is a range of washing cabines “modular” and “multifunction”, where it is possible to wash by spray or immersion”

Enterely built in Stainless Steel with full paneling and safety tray, can be equipped, even later, of additional devices such as tank for immersion washing, air blowing, hot air drying, oil separator, microfiltration.

Standard configuration:

- Construction in Stainless Steel;

- Load capacity 600kg;

- Stainless Steel basket with diameter of 800, 1000, 1200 et 1400mm;

- Basket rotation on vertical axis by gearmotor and clutch;

- Machine with one, two or more tanks;

- Pumps, ramps and noozles in Stainell Steel;

- Tanks with inspection hatch and manual valve for total emptying;

- Washing solution can be heated electrically, by natural gaz, LPG, diesel or steam;

- Stainless Steel pumps;

- Automatic vertical sliding door operated by two pneumatic cylinders and safety microswitch;

- Computer PLC Siemens;

- 500µm static filter in Stainless Steel between washing chamber and tanks;

- Emergency stop;

- Frontal table for basket loading/unloading with dripping tray;

- Vapors extractor;

- CE/UL standards.

SYSTEM:

the SYSTEM series is a range of spray washing cabines for the treatment of metal surfaces, with a washing solution of water and detergent.

Enterely built in carbon steel or Stainless Steel, with dimensions related to the size of the parts to be treated, can be equipped with all devices such as air blowing, hot air drying, oil separator, microfiltration.

Standard configuration:

- Construction in carbon steel or Stainless Steel;

- Load capacity from 400kg to 600kg;

- Stainless Steel basket with dimensions from 800x800mm to 2600x2600mm;

- Basket rotation on vertical axis through gearmotor with clutch;

- Machine with one or two tanks;

- Tanks with inspection hatch and manual valve for total emptying;

- Washing solution can be heated electrically, by natural gaz, LPG, diesel or steam;

- Stainless Steel pumps;

- Automatic vertical sliding door operated by a pneumatic cylinder and safety microswitch;

- Computer PLC Siemens LOGO;

- 500µm static filter in Stainless Steel between washing chamber and tanks;

- Emergency stop;

- Frontal table for basket loading/unloading with dripping tray;

- Vapors extractor;

- CE/UL standards.

MULTI-STAGE:

the Multi-Stage series is a range of linear washing tunnel with suspended load, by spraying and/or immersion, for the treatment of metal surfaces, with a washing solution of water and detergent, designed for high productivity.

Entirely built in Stainless Steel, it is made up of different tanks and sectors as needed (washing, rinsing, blowing, drying, etc.), and can be equipped by all devices such air blowing, hot air drying, Ultrasonics, oil separator, microfiltration.

Configuration:

- Construction in Stainless Steel;

- Load capacity as needed;

- Dimensions de lavage (width, length et height) as needed;

- Motorized transport with suspended load;

- Number of tanks as needed;

- Washing solution heated electrically;

- Pumps, ramps et noozles in Stainless Steel;

- Computer PLC Siemens;

- Static filter in Stainless Steel on each pump suction;

- Microfiltrations;

- Emergency stop;

- Loading/unloading on opposite sides;

- Vapors extractor;

- CE/UL standard.

Configuration and number of tanks and sectors can be customized.

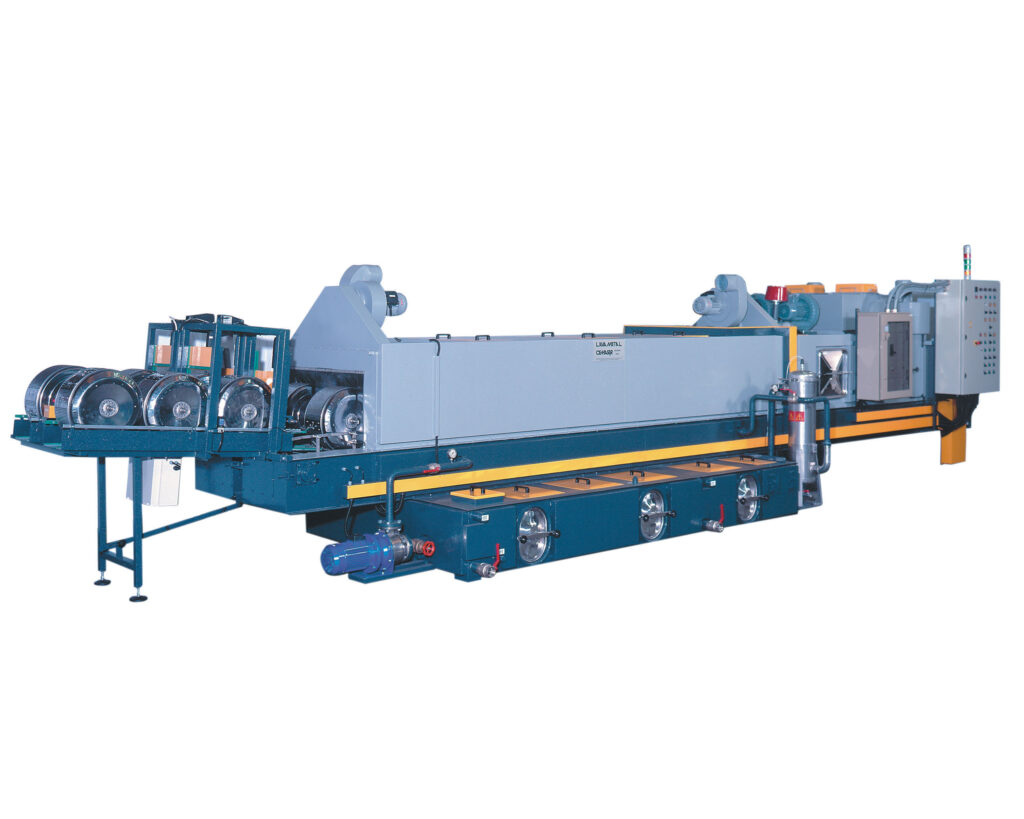

TUNNEL:

the Tunnel series is a range of linear washing tunnels by spraying, for the treatment of metal surfaces, with a washing solution of water and detergent, designed for high productivity.

Entirely built in carbon steel or Stainless Steel, it is made up of different sectors as required (washing, rinsing, blowing, drying, etc.), and can be equipped by all devices such air blowing, hot air drying, oil separator, microfiltration.

Features:

- Construction in carbon steel or Stainless Steel;

- Load capacity as needed;

- Useful washing dimensions as needed

- Motorized conveyor belt by gearmotor and clutch;

- Machine with one or more tanks;

- Tanks with inspection hatch and manual valve for total emptying;

- Washing solution heated electically, by gaz naturel, LPG, diesel or steam;

- Pumps, ramps and noozles in Stainless Steel;

- Computer PLC Siemens;

- 500µm static filter in Stainless Steel between washing sectors and tanks;

- Emergency stop;

- loading/unloading on opposite sides or single frontal side depending on the configuration;

- Manual or robotic loading/unloading;

- Vapors extractor;

- CE/UL standards.

Configuration and number of sectors can be customized.