MAGERLE

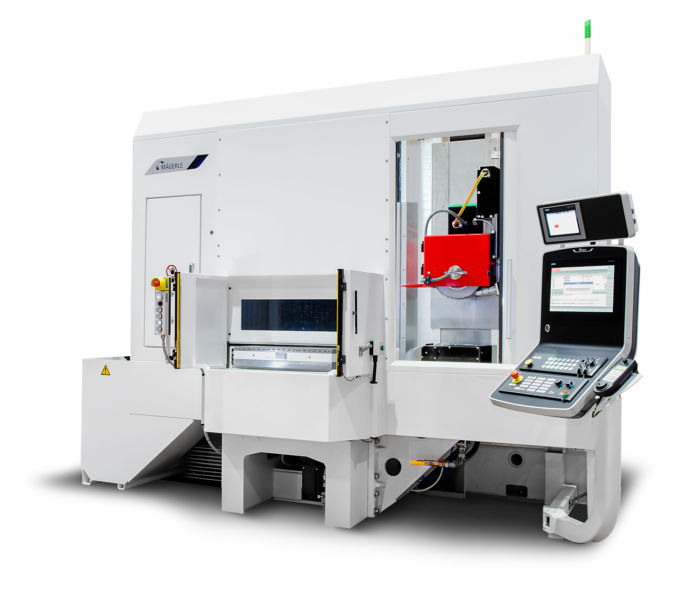

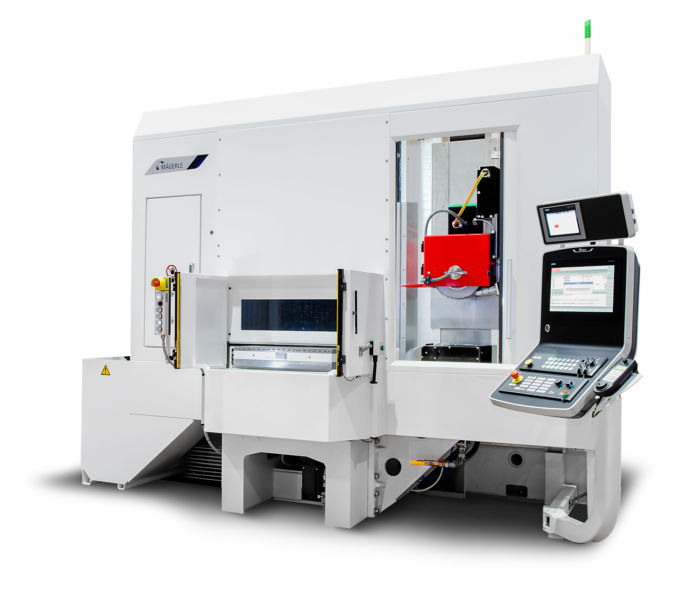

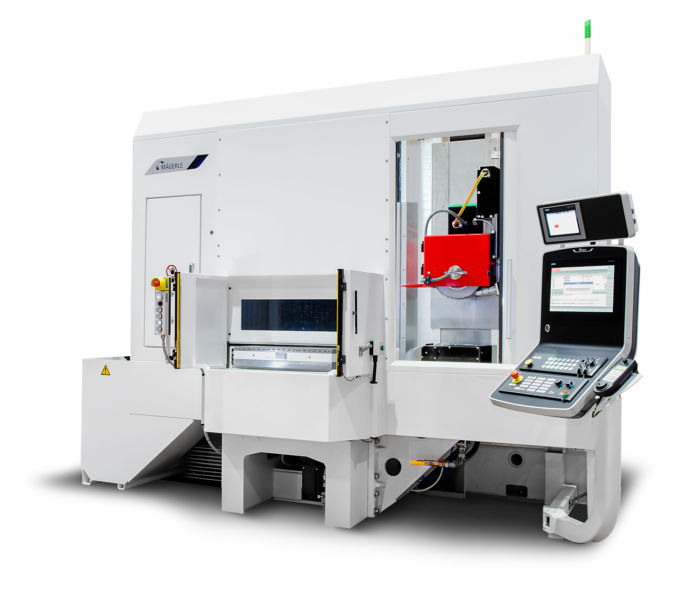

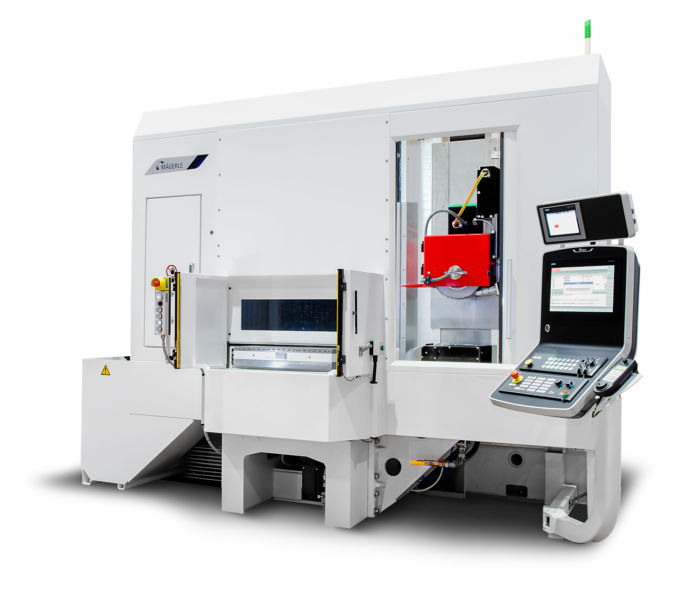

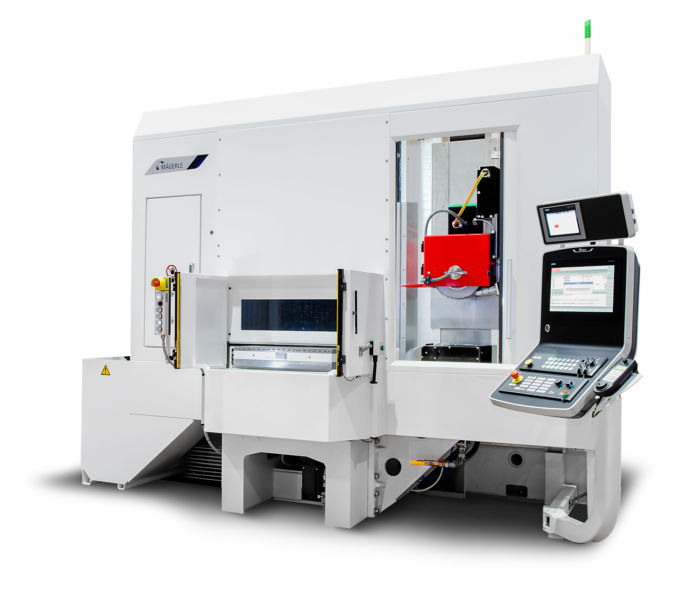

MAGERLE SURFACE - PROFILE GRINDERS

MÄGERLE’s creep feed surface-profile grinders are known for high removal capacity and machining precision. Established in 1929, MÄGERLE grinders are used for simple to multi-face machining of heavy and complex workpieces with just a single clamping operation. They are recognized in the market as high quality grinding machines. MÄGERLE grinders excel in applications where workpieces must be produced in large volume and with high stock removal rates. MÄGERLE grinders are well suited demanding/complex applications in the turbine automotive, aircraft,energy, medical devices/instrumentation and tool making industries.

Thanks to their robust construction, the MÄGERLE machines can run with continuous operation. The MÄGERLE MFP series has a modular design. Table lengths and vertical strokes across a large range can be freely combined with different additional axes and special components. This flexible modular system enables diverse machine configurations, which are precisely geared to the specific user requirements. MÄGERLE machining cells include grinding machines, ATCs, robots, wash and/or cleaning stations and measuring machines.

Models

MFP 5,6-Axis Production Profile Grinder

MFP 30

Max. HP Avail: 35

Travel-XYZ: 19.68″ 17.7″ 19.68″

Tool Changer Positions: 12 or 24

MFP 50

Max. HP Avail: 67

Travel-XYZ: 19.68″ 25.6″ 25.6″

Tool Changer Positions: 24

MFP 51

Max. HP Avail: 67

Travel-XYZ: 19.68″ 25.6″ 25.6″

Tool Changer Positions: 66

MFP 1000

Max. HP Avail: 67

Travel-XYZ: 39.3″ 37.4″ 29.5″

Tool Changer Positions: 30 or 60

MGC With Swiveling Table Production Profile Grinder

MGC 130 ST

Max. HP Avail: 100

Table Size: 29.92″ X 12.79″

Travel-XYZ: 51.1″ 25.59″ 19.68″

MGC 140 ST

Max. HP Avail: 154

Table Size: 29.92″ X 12.79″

Travel-XYZ: 55.11″ 35.43″ 29.52″

MGC 210 ST

Max. HP Avail: 154

Table Size: 39.3″ X 17.3″

Travel-XYZ: 82.67″ 35.43 29.52″

MGC 260 ST

Max. HP Avail: 154

Table Size: 39.3″ X 17.3″

Travel-XYZ: 102.3″ 35.43″ 29.52″

MGC 330 ST

Max. HP Avail: 154

Table Size: 45.2″ X 23.6″

Travel-XYZ: 129.92″ 35.43″ 29.52″