Walter

Walter Tool Grinders

IMS represents WALTER Tool & Cutter grinders in Illinois and Indiana. WALTER offers a complete line of tool grinders which are used to machine and re-sharpen precision cutting tools, like endmills, step drills, drills, reamers, form cutters, thread mills, routers, and more. With up to 5 axes, Walter tool grinders can grind some of the most complex shapes. WALTER is a world leader in the tool grinding industry and has been producing tool grinders since 1953. The machines are designed for high rigidity which guarantees high-precision parts. Walter offers the latest in technology with the industry leading Helitronic Vision that uses linear motor instead of ballscrews and a mineral cast base for the most stable processes and the Diamond series for Erosion of PCD inserted tooling.

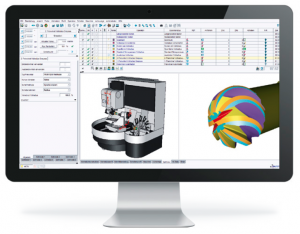

WALTER’s HELITRONIC TOOL STUDIO makes it simple to program complex cutting tools. With minimum complexity, machining steps and movement sequences for both rotationally symmetrical standard tools and for special tools can be programmed by the operator. The tool shown on the screen corresponds exactly to the tool which will then be produced. This means that, as early as the design phase, the result can be checked and, if necessary, corrected thanks to the true-to-life 3D simulation. The operator can quickly find the tool type, the parameters to be entered and the tool by using the assistant.

Additionally, WALTER grinders are supported by their fully automated CNC measuring machines in the HELICHECK series for non-contact complete measurement of tools and production parts. Helicheck machines are able to measure complex cutting tools in a single chucking, including such features as rake angle, lead, helix angle, relief angle and even profile scan. WALTER measuring machines also reduce set up time by accurately measuring your wheels before they go in the machine. Our machines also interface back to the WALTER Tool & Cutter Grinder to automatically input data that allows reverse engineering of tools with no prints. When measuring machines are required, the Helicheck line is a perfect complement to your overall process.

Models

5 AXIS TOOL GRINDING

Helitronic Raptor

Spindles: 2

Max tool Diameter: 320mm

Max Tool Length: 280/350mm

Automation: Option

Helitronic Essential

Spindles: 2

Max tool Diameter: 100mm

Max Tool Length: 185/255mm

Automation: Option

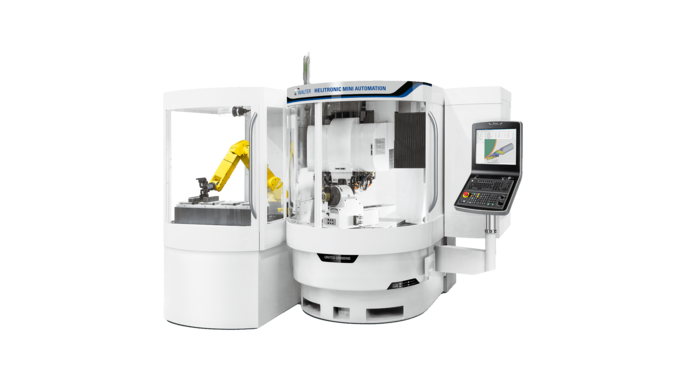

Helitronic MiniAutomation

Spindles: 2

Max tool Diameter: 100mm

Max Tool Length: 185/255mm

Automation: Yes

Helitronic Mini Power

Spindles: 2/ WC 6

Max tool Diameter: 100mm

Max Tool Length: 185/255mm

Automation: Option

Helitronic Power 400

Spindles: WC 4 & 8

Max tool Diameter: 315mm

Max Tool Length: 380/520mm

Automation: Option

Helitronic Micro

Spindles: 3

Max tool Diameter: 3-12.7mm

Max Tool Length: 120/300mm

Automation: Yes

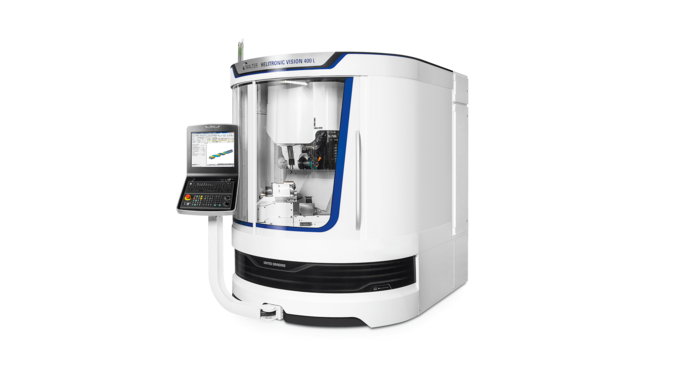

Helitronic Vision 400L

Spindles: WC 4, 8, 12 & 24

Max tool Diameter: 315mm

Max Tool Length: 390/420mm

Automation: Option

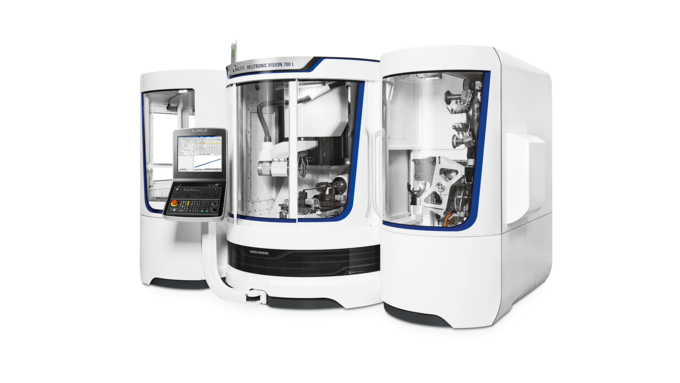

Helitronic Vision 700L

Spindles: WC 12 24

Max tool Diameter: 200mm

Max Tool Length: 580/700mm

Automation: Yes

5 AXIS EROSION MACHINES

Helitronic Diamond Evolution

Spindles: 2

Max tool Diameter: 165mm

Max Tool Length: 185/255mm

Automation: Option

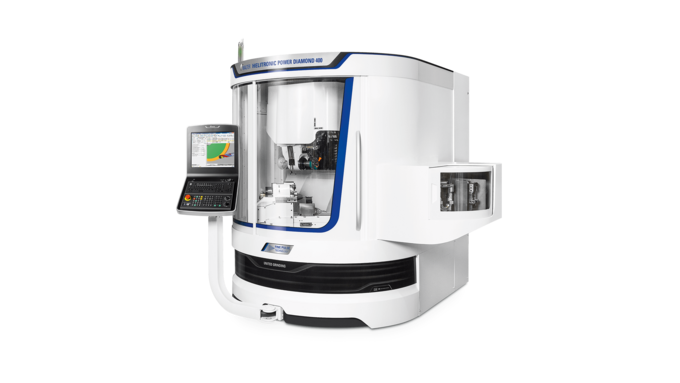

Helitronic Power 400 Diamond

Spindles: WC 4 & 8

Max tool Diameter: 315mm

Max Tool Length: 380/520mm

Automation: Yes

Helitronic Vision Diamond 400L

Spindles: WC 4, 8, 12 & 24

Max tool Diameter: 315mm

Max Tool Length: 390/420mm

Automation: Yes

TOOL AND WHEEL INSPECTION MACHINES

Helicheck 3D/Advanced

Accuracy: E1=(1.8+L/300)µm

Max tool Diameter: 320mm

Max Tool Length: 420mm

Automation: No

Helicheck Pro/Long

Accuracy: E1=(1.2+L/300)µm

Max tool Diameter: 200mm

Max Tool Length: 330/730mm

Automation: Option

Helicheck Plus/Long

Accuracy: E1=(1.4+L/300)µm

Max tool Diameter: 200mm

Max Tool Length: 330/730mm

Automation: Option